Gaskets | Product Gallery

Click to Enlarge Image

Click to Enlarge Image

Flowxer Ring Joint Gasket (Ring Type Joint Gaskets, RTJ Gaskets, Ring type joint)

Flowxer Spiral Wound Gasket (SPW Gaskets) & Low Stress Gasket

Flowxer Metal Double Jacketed, Metal Single Jacketed Gaskets, Heat Exchanger Gaskets

Kammprofile Gasket, (Kammprofile Gaskets, Serrated Gaskets, Cam profile gaskets)

Flowxer Tanged Insert Graphite Gaskets

Flowxer Metal Bonded Rubber Gaskets

Flowxer Insulating Flange Kit Gaskets (Insulating kits, Insulation kits)

Flowxer Corrugated Metal Graphite Gasket

Flowxer Non Asbestos Gasket Sheets (Asbestos Free Gaskets, CNAF gaskets)

Flowxer Metal Gaskets (Metallic Gaskets)

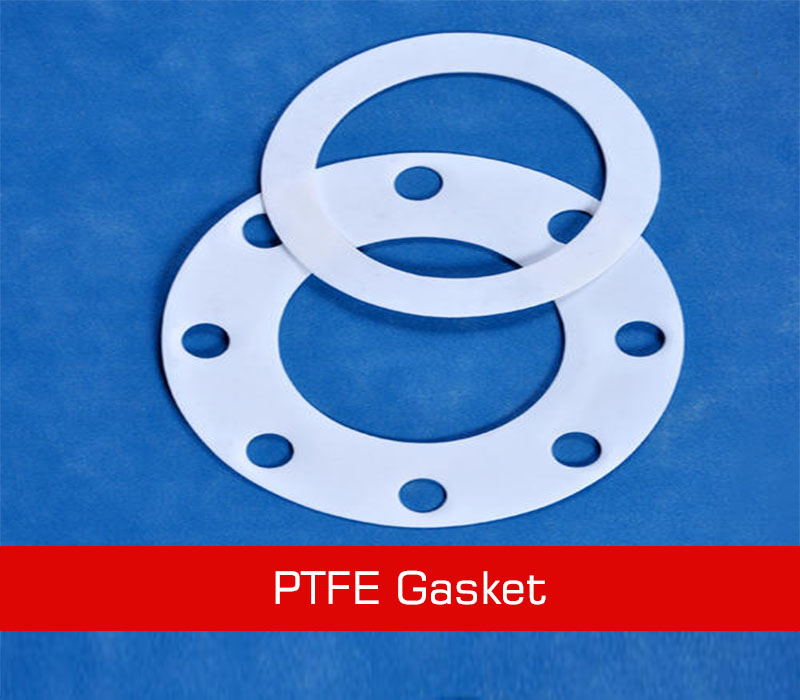

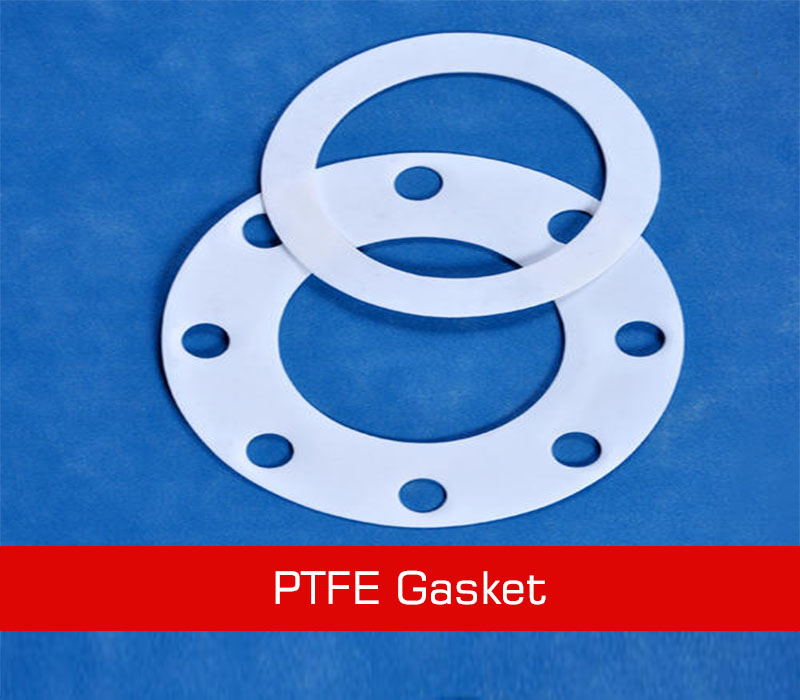

Flowxer PTFE / Expanded PTFE Gasket, Gasket Sheets, Rods

Flowxer Flexible Graphite Gaskets / Gasket Sheets / Packings

Flowxer Rubber Gaskets / Gasket Sheets / Tapes

Flowxer High Temperature Gaskets / Gasket Materials

Flowxer High Pressure Gaskets / Gasket Materials

Our products are always well-supplied through national / international sources guaranteeing 100% product conformity to the manufacturing standard and customer specification.

Commercial quality sheet steel with an upper temperature limit of approximately 1000º F., particularly if conditions are oxidizing. Not suitable for handling crude acids or aqueous solutions of salts in the neutral or acid range. A high rate of failure may be expected in hot water service if the material is highly stressed, Concentrated acids and most alkalies have little or no action on iron and steel gaskets which are used regularly for such services.

An 18-8 (Chromium 18-20%, Nickel 8-10%) Stainless with a maximum recommended working temperature of 1400º F

At least 80% of applications for non-corrosive services can use Type 304 Stainless in the temperature range of -320 F to 1000º F.

Excellent corrosion resistance to a wide variety of chemicals.

Subject to stress corrosion crackling and to intergranular corrosion at temperatures between 800º F to 1500º F in presence of certain media for prolonged periods of time.

An 18-12 Chromium-Nickel steel with approximately 2% of Molybdenum added to the straight 18-8 alloy which increases its strength at elevated temperatures and results in somewhat improved corrosion resistance.

Has the highest creep strength at elevated temperatures of any conventional stainless type.

Not suitable for extended service within the carbide precipitation range of 800º F to 1650º F. when corrosive conditions are severe.

Recommended maximum working temperature of 1400º F.

Continuous maximum temperature range of 1400º F -1500º F.

Carbon content held at a maximum of .03%.

Subject to a lesser degree of stress corrosion cracking and also to intergranular corrosion than Type 316.

An 18-10 Chromium-Nickel steel with a Titanium addition.

Type 321 stainless has the same characteristics as Type 347.

The recommended working temperature is 1400º F to 1500º F. and in some instances 1600º F.

An 18-10 Chromium-Nickel steel with the addition of Columbium.

Not as subject to intergranular corrosion as is Type 304.

Is subject to stress corrosion.

Recommended working temperature of 1400º F -1500º F and in some instances to 1700º F.

A 12% Chromium steel with a maximum temperature range of 1200º F. to 1300º F.

Used for applications requiring good resistance to sealing at elevated temperatures.

Is not recommended for use where severe corrosion in encounteblue but is still very useful for some chemical application.

May be used where dampness, alone or coupled with chemical pollution, causes steel to fail quickly.

4-6% Chromium and 1/2% Molybdenum alloyed for mild corrosive resistance and elevated service. Maximum working temperature is 1200º F.

If severe corrosion is anticipated, a better grade of stainless steel would probably be a better choice. Becomes extremely hard when welded.

Arsenical Admiralty 443 has 71% Copper, 28% Zinc, 1% Tin and trace amounts of Arsenic.

High corrosive resistance, holds up extremely well against salt and brackish waters, and water containing sulfides.

Recommended maximum working temperature of 500º F.

Ideal for carrying corrosive cooling waters at relatively high temperatures.

45% Iron, 24% Nickel, 20% chromium, and small amounts of Molybdenum and Copper.

Maximum temperature range of 1400º F -1500º F.

Developed specifically for applications requiring resistance to corrosion by sulfuric acid.

Brinell hardness is about 160.

Alloy 110 is commercially pure (99% minimum).

Its excellent resistance and workability makes it ideal for double jacketed gaskets.

For solid gaskets, stronger alloys like 5052 and 3003 are used.

Maximum continuous service temperature of 800º F.

Yellow brass 268 has 66% Copper and 34% Zinc.

Offers excellent to good corrosion resistance in moist environments, but is not suitable for such materials as acetic acid, acetylene, ammonia, and salt. Maximum recommended temperature limit of 500 F.

Nearly pure copper with trace amounts of silver added to increase its working temperature.

Recommended maximum continuous working temperature of 500º F.

Contains 69% Copper, 30% Nickel and small amounts of Manganese, Zinc and Iron.

It is mostly used in sea water applications, where lesser resistant alloys rapidly deteriorate.

Maximum recommended temperature limit 500º F.

26-30% Molybdenum, 62% Nickel and 4-6% Iron.

Maximum temperature range of 2000º F. resistant to hot, concentrated hydrochloric acid.

Also resists the corrosive effects of wet hydrogen chlorine gas, sulfuric and phosphoric acids and blueucing salt solutions.

Useful for high temperature strength.

16-18% Molybdenum, 13-17.5% Chromium, 3.7-5.3% Tungsten, 4.5-7% Iron and the balance is Nickel. Maximum temperature range of 2000º F.

Very good in handling corrosives.

High resistance to cold nitric acid of varying concentrations as well as boiling nitric acid up to 70% concentration.

Good resistance to hydrochloric acid and sulfuric acid.

Excellent resistance to stress corrosion cracking.

Recommended working temperatures of 2000º F. and is some instances 2150º F.

Is a nickel base alloy containing 77% Nickel, 15% Chromium and 7% Iron, Excellent high temperature strength.

Frequently used to overcome the problem of stress corrosion.

Has excellent mechanical properties at the cryogenic temperature range.

32.5% Nickel, 46% Iron, 21% Chromium, resistant to elevated temperatures, oxidation and carburization. Recommended maximum temperature of 1600º F.

Maximum temperature range of 1500º F.

Contains 67% Nickel and 30% Copper.

Excellent resistance to most acids and alkalies, except strong oxidizing acids.

Subject to stress corrosion, cracking when exposed to fluorosilic acid, mercuric chloride and mercury, and should not be used with these media.

With PTFE (Polytetrafluoroethylene), it is widely used for hydrofluoric acid service.

Recommended maximum working temperature is 1400º F. and even higher under controlled conditions. Corrosion resistance makes it useful in caustic alkalies and where resistance to corrosion, in structural applications, is a prime consideration.

Does not have the all around excellent resistance of Monel.

90-95% Copper, 5-10% Tin and trace amounts of phosphorus.

Maximum temperature range of 500º F.

Maximum temperature range of 500º F.

Limited to low temperature steam applications.

Excellent corrosion resistance, but not suitable for acetylene, ammonia, chromic acid, mercury and potassium cyanide.

Maximum temperature range of 2000ºF.

Excellent corrosion resistance even at high temperatures.

Known as the "Best solution" to chloride ion attack.

Resistant to nitric acid in a wide range of temperatures and concentrations.

Most alkaline solutions have little if any effect upon it.

Outstanding in oxidizing environments.

Note: Maximum temperature ratings are based upon hot air constant temperatures. The presence of contaminating fluids and cyclic conditions may drastically affect the maximum temperature range.

We believe in making sure that our products are always well-supplied through various national & international sources. This guarantees 100% product conformity to the manufacturing specifications as required by our customers.

We have been manufacturing gaskets for over three decades now and this gives us an edge over our competitors.

Our R&D team is constantly ensuring that our products are always in line with the latest industrial trends. By exploring innovative solutions we are able to ensure that our customers’ requirements are fulfilled.

We have complete control over all critical processes including inflow of raw materials before being processed.

Our products are favored by reputed petroleum, oil & gas companies.

Our team of engineers ensures that no stone is left unturned in tackling any technical challenges they face.

We are known for our ability to design products based on special specifications.

Working closely with user groups has helped us work on developing customized products and understanding customer requirements better.

Our facilities are capable of meeting customers’ emergency and shutdown product requirements at any specified time all throughout the year.

Our gaskets are made of various materials like Soft Iron, F5, 304, 304L, 316, 316L, 316Ti, 321, 347, MONEL® 400, Inconel® 600, 625, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper, Brass, Duplex, Super Duplex etc.

We have alliances with distributors all over the world which gives us a competitive advantage and also helps us provide speedy delivery in various locations.

| Type | Download Link (PDF) |

|---|---|

|

Class 150-2500 - NPS 1/2-36 |

Download |

| Type | Download Link (PDF) |

|---|---|

|

EN 1514-2 for use with Flanges DIN EN 1092-1 |

Download |

| Type | Download Link (PDF) |

|---|---|

|

Class 150-600 - NPS 26-60 |

Download |

| Type | Download Link (PDF) |

|---|---|

|

Class 150-600 - NPS 26-60 |

Download |

LTS has a combined set up of machineries and skilled man power to provide emergency supplies of Gaskets. Flanges Control Valve Parts and Mounting Brackets.

Our vast experience in manufacturing, extensive research and new product development is targeted to deliver new materials and products that meet your extremely urgent requirement. On-site advice is provided by highly skilled technical team. We possess the specialized knowledge, practical experience and technical facilities to solve your specific needs.

Fastest Delivery ,Technical Support & On-Site Advice. We maintain exclusive tie up with DHL, FEDEX, BLUEDART, UPS etc to cover all the major towns and cities across the globe.

Use this form to send us your Query / Message / Feedback and our Sales / Technical Team will get in touch with you !