Product Gallery

Click to Enlarge Image

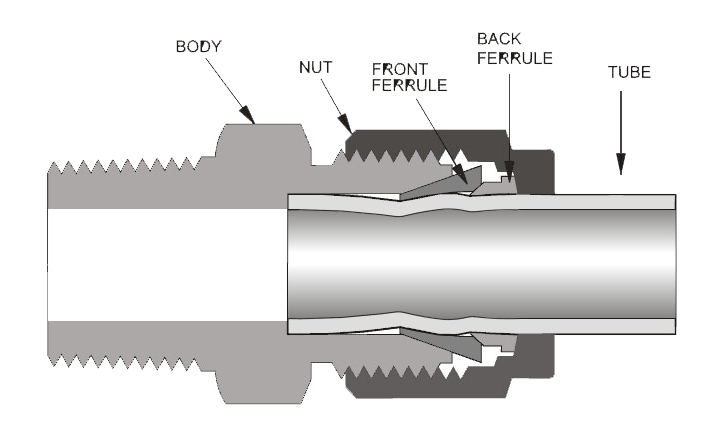

Low Torque Assembly

Positive leak free seal assembly and reassembly

Variety of end connection and patterns

Used to seal and to grip the tubing

Leak tight assembly

Tolerance tested

Does not require soldering

Comparatively quick and easy to use

Can sustain high pressure and toxic gases

Flare less design.

Available for metric and fractional (imperial inch size) tubes with choice of NPT/BSPT/BSP/SAE/ISO pipe threads.

Wide range of sizes and configurations.

Manufacture in wide range of material like Stainless Steel,Steel, Brass, Aluminum, Titanium, Hastalloy, Monel and other special alloys

All components of fittings are made of same material Excellent make and remake life.

Interchangeable with leading international brands.

Suitable with thin or thick walled tubes.

Fittings are tested for high pressure, vacuum, impulse, vibration and temperature to ensure safely

Double/Twin Ferrule Fittings Standard Configurations |

||||

| Main Tubing | Connection Type | Inter Connection or End Connection | Instrument Side | |

| Tube Closure | Plug |

|

||

| Cap | ||||

| Weld Connector | Nut | |||

| Ferrule Set | ||||

| Tube to Tube | Straight | |||

| Elbow | ||||

| Tee | ||||

| Cross | ||||

| Bulk Head | ||||

| Tube to Male | Male Stud | |||

| Male Elbow | ||||

| Male Tee | ||||

| Female Connector | Female Straight | |||

| Elbow | ||||

| Tee | ||||

Click to Enlarge Image

LTS has a combined set up of machineries and skilled man power to provide emergency supplies of Gaskets. Flanges Control Valve Parts and Mounting Brackets.

Our vast experience in manufacturing, extensive research and new product development is targeted to deliver new materials and products that meet your extremely urgent requirement. On-site advice is provided by highly skilled technical team. We possess the specialized knowledge, practical experience and technical facilities to solve your specific needs.

Fastest Delivery ,Technical Support & On-Site Advice. We maintain exclusive tie up with DHL, FEDEX, BLUEDART, UPS etc to cover all the major towns and cities across the globe.

Use this form to send us your Query / Message / Feedback and our Sales / Technical Team will get in touch with you !